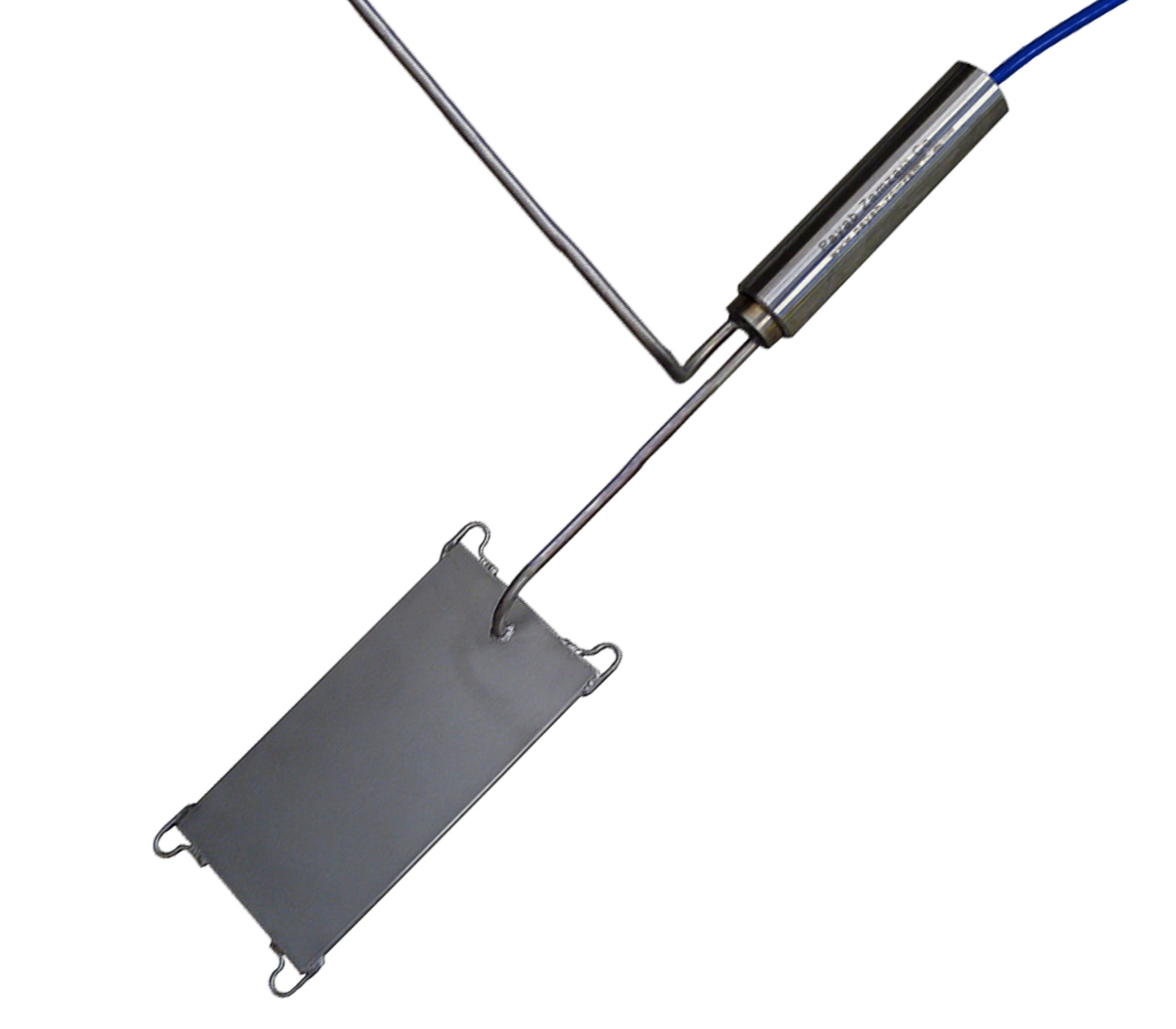

Shotcrete Pressure Cell – PCCS01

A shotcrete pressure cell is in many ways similar to ordinary pressure cells but these are used to monitor the stresses acting on a shotcrete lining instead. Since the thickness of sprayed shotcrete is usually in the range of 5-15 Cm, it is not thick enough to accommodate a usual size pressure cell. For the shotcrete to accommodate a pressure cell, this instrument is reshaped to a rectangular form so that its small width can be buried in the shotcrete thickness direction. Due to the variety of thickness and locations for shotcrete, these pressure cells are manufactured in many sizes and aspect ratios. Another specification for a shotcrete pressure cell is an additional tube attached to the cell body (called Compensation Tube). This tube is filled with the same liquid as in the main cell and is connected to it. When the shotcrete (or concrete) is hardened, it usually shrinks. This tube is then pressed to compensate for the liquid which is required to bring the cell diaphragm in contact with the shotcrete again

Application

Some of the applications of this instrument are:

- Monitoring actual pressure in shotcreted tunnels

- Recording active pressure in concrete linings thinner than 20cm

Operation and Installation

To install a shotcrete pressure cell in a tunnel, a soft cement mortar is applied on the rock surface or on the welded mesh. The cell is then pushed on this mortar making sure no air is entrapped under the cell. Using four eye shaped steel loops around the cell, it is fixed to the mesh to make sure it remains in its assigned location while applying shotcrete. Before shotcreting, another layer of soft mortar is applied on the cell to reduce shotcrete rebound. After hardening of the sprayed shotcrete, the compensation tube is pressed till a small increase in the cell pressure is recorded from the cell transducer. This guarantees that the location is prepared by laying a soft layer of soil. The cell is placed on the layer and is covered by similar soft material. Additional material is then placed on the cell and is compacted with hand compactors. When the thickness of the covering cement shrinkage has been overcome

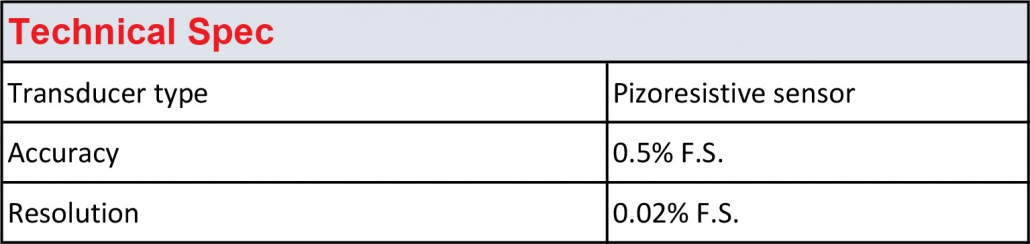

Technical Spec

Order information

- PCCS01 – AAA – BB – CC – DD

- AAA (Pressure range in Bars): 10, 20, 40 , 60

- BB: cable length in meters

- CC: Pad size in cm (8×25 cm standard Version

- DD: Compensation tube length in cm